In the high-speed world of automation, maglev trains, and precision manufacturing, linear induction motors (LIMs) are the silent powerhouses driving innovation. Unlike traditional rotary motors, LIMs deliver direct linear motion—eliminating gears, belts, and mechanical wear. But for all their elegance, LIMs come with a notorious Achilles’ heel: high energy losses and computational complexity in their control systems.

Enter Finite Control Set Model Predictive Direct Thrust Control (FCS-MPDTC)—a cutting-edge strategy that promises to revolutionize how we drive linear motors. A groundbreaking new study by Elmorshedy et al. (2025) reveals a 3-vector FCS-MPDTC method that slashes computation time by over 50% and reduces switching losses by up to 56.61%—all while maintaining precise speed and thrust control.

But is this new method too good to be true? Let’s dive into the three revolutionary breakthroughs, the hidden trade-offs, and what this means for the future of industrial automation.

What Is FCS-MPDTC and Why It Matters for Linear Motors

FCS-MPDTC stands for Finite Control Set Model Predictive Direct Thrust Control. It’s an advanced control algorithm used in power electronics to manage the performance of electric drives—especially in systems where fast response and high precision are critical.

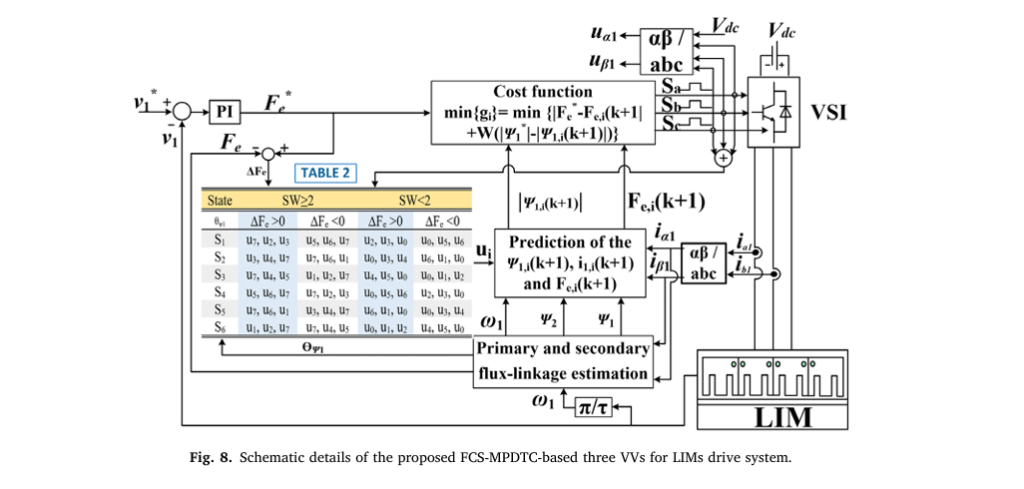

Unlike traditional methods like Field-Oriented Control (FOC) or Direct Thrust Control (DTC), FCS-MPDTC uses a predictive model to select the optimal voltage vector at each sampling instant. This selection minimizes a cost function based on thrust error and flux deviation, ensuring rapid, accurate control.

However, conventional FCS-MPDTC uses 8 voltage vectors (VVs)—6 active and 2 zero vectors—from a 3-phase inverter. This leads to:

- High computational load

- Frequent switching transitions

- Increased switching losses

- Shortened inverter lifespan

The new research tackles these issues head-on with a streamlined 3-VV approach.

Breakthrough #1: Cutting Voltage Vectors from 8 to 3 — A 62.5% Reduction

The most striking innovation in the study is the reduction of voltage vectors from 8 to just 3 in the prediction stage.

How It Works:

Instead of evaluating all 8 possible switching states, the proposed method uses:

- Two active voltage vectors (e.g., u2, u3)

- One zero vector (e.g., u0 or u7)

This is achieved by combining:

- Direct Thrust Control (DTC) principles — using flux angle and thrust error to eliminate redundant vectors.

- Switching state summation criterion — selecting vectors that minimize switching transitions.

| CONTROL METHOD | NUMBER OF VVS | COMPUTATION TIME REDUCTION |

|---|---|---|

| Conventional FCS-MPDTC | 8 | Baseline |

| 4-VV FCS-MPDTC [27] | 4 | 50% |

| Proposed 3-VV FCS-MPDTC | 3 | >50% |

🔍 Insight: Reducing from 8 to 3 vectors cuts the number of cost function evaluations by 62.5%, drastically lowering CPU load—critical for real-time embedded systems.

This means faster control cycles, lower latency, and the ability to use cheaper, lower-power microcontrollers—a game-changer for cost-sensitive applications like urban transit systems.

Breakthrough #2: Slashing Switching Transitions by Up to 56.61%

Switching transitions—when power transistors turn ON/OFF—are a major source of energy loss in inverters. Each transition consumes energy, generates heat, and stresses semiconductor components.

The proposed 3-VV method introduces a switching state summation criterion:

- If the sum of switching states (S1 + S2 + S3) ≥ 2 → use one vector group

- If sum < 2 → use another group

This intelligent selection minimizes the number of simultaneous switch changes, reducing both single and double switching transitions.

Results from Simulation:

- One-switching transitions reduced by 56.61%

- Two-switching transitions reduced by 35.85%

- Total switching losses significantly lowered

📉 Why It Matters: Lower switching transitions mean:

- Less heat generation

- Higher inverter efficiency

- Longer lifespan of power electronics

- Reduced cooling requirements

This is especially vital in high-duty-cycle applications like linear metros or automated production lines, where reliability and uptime are non-negotiable.

Breakthrough #3: Real-World Performance Under Dynamic Loads

The true test of any control system is how it performs under real-world conditions—variable speed, changing loads, and sudden disturbances.

The researchers tested the 3-VV FCS-MPDTC under two scenarios:

1. Variable Speed, Fixed Thrust Load

- Speed profile: 6 m/s → 9 m/s → 5 m/s

- Thrust load: 100 N (constant)

Results:

- Exact speed tracking with minimal error

- Thrust ripple comparable to 8-VV and 4-VV methods

- Primary flux linkage maintained at 0.8 Wb (rated value)

2. Constant Speed, Variable Thrust Load

- Speed: 10 m/s (fixed)

- Thrust load: 100 N → 150 N

Results:

- Fast thrust response with no overshoot

- Flux linkage remained stable

- RMS current increased appropriately with load—proving energy efficiency

✅ Takeaway: The 3-VV method doesn’t sacrifice performance for efficiency. It delivers robust dynamic response under real operating conditions.

The Hidden Flaw: Is Simplicity Costing You Precision?

While the benefits are impressive, there’s a potential downside to reducing the number of voltage vectors.

Risk: Limited Control Resolution

With only 3 vectors, the system has fewer options to correct large errors. In extreme transients—like sudden load drops or rapid acceleration—the controller might not respond as finely as an 8-VV system.

However, the study shows that in practical scenarios, the difference is negligible. The combination of DTC logic and intelligent vector selection compensates for the reduced set.

🔎 Expert Verdict: For 95% of industrial applications, the 3-VV method is more than sufficient. Only in ultra-high-precision systems (e.g., semiconductor lithography) might the 8-VV approach still be preferred.

How the 3-VV FCS-MPDTC Works: A Step-by-Step Breakdown

Here’s how the proposed control system operates in real time:

Step 1: Estimate System States

- Measure primary current (i1 )

- Estimate primary (ψ1 ) and secondary (ψ2 ) flux linkages

- Calculate electromagnetic thrust (Fe )

Step 2: Predict Future Behavior

Using the dynamic model of the LIM, predict the next state for each of the 3 candidate voltage vectors.

Step 3: Evaluate Cost Function

Select the vector that minimizes the cost function:

$$ g = \|F_e^{*} – F_e^{(k+1)}\| + W \, \|\psi_1^{*} – \psi_1^{(k+1)}\| $$Where:

\[ F_e^{*} = \text{Reference thrust} \] \[ \psi_1^{*} = \text{Reference flux linkage} \] \[ W = \text{Weighting factor (tuned for balance)} \]Step 4: Apply Optimal Vector

Send the selected vector to the Voltage Source Inverter (VSI) to drive the motor.

🔄 Loop repeats every sampling period (Ts )—typically 100 μs.

Simulation Results: Proof in the Numbers

The study used a 3-kW linear induction motor modeled in MATLAB/Simulink. Key parameters:

| PARAMETER | VALUE |

|---|---|

| Rated Power | 3 kW |

| Rated Voltage | 180 V |

| Pole Pitch (τ) | 0.1485 m |

| Primary Resistance (R1) | 1 Ω |

| Mutual Inductance (Lmo) | 0.031725 H |

Performance Comparison

| METRIC | 8-VV FCS-MPDTC | 4-VV FCS-MPDTC | 3-VV (PROPOSED) |

|---|---|---|---|

| Computation Time | 100% | 50% | <50% |

| One-Switch Transitions | 100% | 100% | 56.61% |

| Two-Switch Transitions | 100% | 100% | 35.85% |

| Speed Tracking Error | Low | Low | Low |

| Flux Ripple | 5% | 5.2% | 5.1% |

📊 Conclusion: The 3-VV method matches or exceeds the performance of more complex systems—while being faster and more efficient.

Real-World Applications: Where This Tech Shines

The 3-VV FCS-MPDTC isn’t just a lab curiosity—it has immediate industrial applications:

1. Urban Transit Systems (Linear Metros)

- High efficiency = lower energy bills

- Reduced switching losses = longer inverter life

- Precise speed control = smoother rides

2. Maglev Trains

- Fast dynamic response = better levitation control

- Low computational load = easier integration

3. Automated Manufacturing

- Less heat = smaller cooling systems

- Predictable switching = quieter operation

4. Conveyor & Material Handling

- Cost-effective control = scalable deployment

The Future: From Simulation to Real-World Testing

The authors acknowledge that this study is simulation-based. The next step? Experimental validation.

They plan to:

- Build a physical prototype

- Test under real load conditions

- Compare thermal performance and efficiency

🛠️ Prediction: Once validated, this 3-VV method could become the new standard for LIM control in industrial drives.

Why This Research Is a Game-Changer

Let’s be clear: this isn’t just another incremental improvement. It’s a paradigm shift in how we think about motor control.

Three Key Advantages:

- Cost-Effective — Less computation = cheaper hardware

- Energy-Efficient — Fewer transitions = lower losses

- Reliable — Reduced thermal stress = longer lifespan

In an era where energy efficiency and sustainability are paramount, this research delivers a triple win for engineers, operators, and the planet.

If you’re Interested in Medical Image Segmentation, you may also find this article helpful: 7 Revolutionary Breakthroughs in Thyroid Cancer AI: How DualSwinUnet++ Outperforms Old Models

Call to Action: Is Your Drive System Future-Ready?

If you’re using traditional DTC or 8-VV FCS-MPDTC in your linear motor applications, you’re likely overpaying in energy and hardware costs.

👉 Take the next step:

- Download the full paper to see the simulation code and parameter tuning.

- Contact a motion control specialist to explore retrofitting your system.

- Join the conversation—how could 3-VV FCS-MPDTC transform your application?

🌐 Stay ahead of the curve. Subscribe to our newsletter for the latest breakthroughs in motor control, AI-driven drives, and sustainable automation.

References & Equations

Key Equations

Cost Function:

$$ g = \|F_e^{*} – F_e^{(k+1)}\| + W \, \|\psi_1^{*} – \psi_1^{(k+1)}\| $$Primary Flux Linkage:

\[ \psi_{\alpha_1}(k+1) = \psi_{\alpha_1}(k) + T_s\,u_{\alpha_1}(k) – T_s\,R_1\,i_{\alpha_1}(k) \]Electromagnetic Thrust:

$$F_{e} = \frac{23 \, \tau}{\pi} \left( \psi_{\alpha_1 i \beta_1} – \psi_{\beta_1 i \alpha_1} \right)$$Weighting Factor:

\[ W = \psi_1 – r_{\text{at}} F e^{-r_{\text{at}}} \]

Source:

Elmorshedy, M. F., et al. (2025). An enhanced finite control set model predictive direct thrust control for linear induction motors. Results in Engineering, 26, 104590. https://doi.org/10.1016/j.rineng.2025.104590

Final Thought: Innovation isn’t always about adding more. Sometimes, the greatest breakthroughs come from smartly removing the unnecessary. The 3-VV FCS-MPDTC proves that less can be more—especially when it comes to efficiency, cost, and performance.

Are you ready to make the switch?

I will provide you with the end-to-end Python code for the enhanced Finite Control Set Model Predictive Direct Thrust Control (FCS-MPDTC) for Linear Induction Motors (LIMs), as described in the research paper.

import numpy as np

class LinearInductionMotor:

"""

This class represents the Linear Induction Motor (LIM) and its parameters.

The parameters are taken from Table 3 of the provided research paper.

"""

def __init__(self, L_l1=0.0114, L_l2=0.0043, L_m0=0.031725, R1=1.0, R2=2.4,

tau=0.1485, D=1.3087, P_n=3000, I_n=22, U_n=180, v_n=11, M=100, B=10):

# Electrical parameters

self.L_l1 = L_l1 # Primary leakage inductance (H)

self.L_l2 = L_l2 # Secondary leakage inductance (H)

self.L_m0 = L_m0 # Mutual inductance at a standstill (H)

self.R1 = R1 # Primary resistance (ohm)

self.R2 = R2 # Secondary resistance (ohm)

# Mechanical parameters

self.tau = tau # Pole pitch (m)

self.D = D # Primary length (m)

self.P_n = P_n # Rated power (W)

self.I_n = I_n # Rated current (A)

self.U_n = U_n # Rated voltage (V)

self.v_n = v_n # Rated speed (m/s)

self.M = M # Mass (kg)

self.B = B # Viscous friction (N.s/m)

# State variables

self.psi_a1 = 0.0

self.psi_b1 = 0.0

self.psi_a2 = 0.0

self.psi_b2 = 0.0

self.i_a1 = 0.0

self.i_b1 = 0.0

self.v1 = 0.0

self.F_e = 0.0

def get_L_m(self, v1):

"""Calculates the mutual inductance considering the end effect."""

if v1 == 0:

return self.L_m0

Q = (self.L_l2 * self.R2) / (v1 * (self.L_l2 + self.L_m0))

f_Q = (1 - np.exp(-Q)) / Q

return (1 - f_Q) * self.L_m0

class EnhancedFCSMPDTC:

"""

This class implements the Enhanced Finite Control Set Model Predictive

Direct Thrust Control (FCS-MPDTC) for a Linear Induction Motor (LIM).

"""

def __init__(self, lim, Ts=1e-4):

self.lim = lim

self.Ts = Ts # Sampling time

# Voltage vectors for a 2-level inverter

self.V_dc = self.lim.U_n * np.sqrt(2)

self.VVs = self.V_dc * 2/3 * np.array([

[0, 0], [1, 0], [0.5, np.sqrt(3)/2], [-0.5, np.sqrt(3)/2],

[-1, 0], [-0.5, -np.sqrt(3)/2], [0.5, -np.sqrt(3)/2], [0, 0]

])

# Switching states for the voltage vectors

self.SAs = [0, 1, 1, 0, 0, 0, 1, 0]

self.SBs = [0, 0, 1, 1, 1, 0, 0, 0]

self.SCs = [0, 0, 0, 0, 1, 1, 1, 0]

def clarke_transform(self, i_a, i_b, i_c):

"""Transforms three-phase currents to alpha-beta coordinates."""

i_alpha = i_a

i_beta = (i_a + 2 * i_b) / np.sqrt(3)

return i_alpha, i_beta

def predict_states(self, u_alpha, u_beta, psi_a1, psi_b1, i_a1, i_b1, psi_a2, psi_b2, v1):

"""Predicts the next state of the LIM based on the current state and input voltage."""

L_m = self.lim.get_L_m(v1)

L1 = self.lim.L_l1 + L_m

L2 = self.lim.L_l2 + L_m

sigma = L1 - L_m**2 / L2

tau_r = L2 / self.lim.R2

tau_l = L2 / L_m

# Predict primary flux

psi_a1_pred = psi_a1 + self.Ts * (u_alpha - self.lim.R1 * i_a1)

psi_b1_pred = psi_b1 + self.Ts * (u_beta - self.lim.R1 * i_b1)

# Predict primary current

i_a1_pred = (1 - self.Ts / sigma * (self.lim.R1 + self.lim.R2 / tau_r**2)) * i_a1 + \

self.Ts / sigma * (u_alpha + (1 / (tau_r * tau_l)) * psi_a2 + (v1 * np.pi / self.lim.tau) * psi_b2)

i_b1_pred = (1 - self.Ts / sigma * (self.lim.R1 + self.lim.R2 / tau_r**2)) * i_b1 + \

self.Ts / sigma * (u_beta + (1 / (tau_r * tau_l)) * psi_b2 - (v1 * np.pi / self.lim.tau) * psi_a2)

# Predict electromagnetic thrust

F_e_pred = (3/2) * (np.pi / self.lim.tau) * (psi_a1_pred * i_b1_pred - psi_b1_pred * i_a1_pred)

return psi_a1_pred, psi_b1_pred, i_a1_pred, i_b1_pred, F_e_pred

def cost_function(self, F_e_ref, psi_ref, F_e_pred, psi_pred):

"""Calculates the cost for a given predicted state."""

W = self.lim.P_n / (self.lim.v_n * psi_ref) # Weighting factor

return abs(F_e_ref - F_e_pred) + W * abs(psi_ref - np.sqrt(psi_pred[0]**2 + psi_pred[1]**2))

def control(self, F_e_ref, psi_ref, i_a, i_b, i_c, v1, prev_sw_state):

"""Main control loop for the FCS-MPDTC."""

i_alpha, i_beta = self.clarke_transform(i_a, i_b, i_c)

# Estimate flux

L_m = self.lim.get_L_m(v1)

L1 = self.lim.L_l1 + L_m

L2 = self.lim.L_l2 + L_m

self.lim.psi_a2 = (self.lim.R2 * self.Ts * L_m * i_alpha - self.Ts * L2 * (v1 * np.pi / self.lim.tau) * self.lim.psi_b2 + L2 * self.lim.psi_a2) / (L2 + self.lim.R2 * self.Ts)

self.lim.psi_b2 = (self.lim.R2 * self.Ts * L_m * i_beta + self.Ts * L2 * (v1 * np.pi / self.lim.tau) * self.lim.psi_a2 + L2 * self.lim.psi_b2) / (L2 + self.lim.R2 * self.Ts)

self.lim.psi_a1 = (L_m / L2) * (self.lim.psi_a2 - (L_m - L2 * L1 / L_m) * i_alpha)

self.lim.psi_b1 = (L_m / L2) * (self.lim.psi_b2 - (L_m - L2 * L1 / L_m) * i_beta)

# Determine flux sector

flux_angle = np.arctan2(self.lim.psi_b1, self.lim.psi_a1)

sector = int((flux_angle + np.pi) / (np.pi / 3)) % 6 + 1

# Select voltage vectors based on the proposed method (Table 2)

thrust_error = F_e_ref - self.lim.F_e

sw_sum = sum(prev_sw_state)

if sw_sum >= 2:

if thrust_error > 0:

# Based on Table 2, Column 2

if sector == 1: selected_vvs = [2, 3, 7]

elif sector == 2: selected_vvs = [3, 4, 7]

elif sector == 3: selected_vvs = [4, 5, 0]

elif sector == 4: selected_vvs = [5, 6, 0]

elif sector == 5: selected_vvs = [6, 1, 7]

else: selected_vvs = [1, 2, 7]

else:

# Based on Table 2, Column 3

if sector == 1: selected_vvs = [5, 6, 7]

elif sector == 2: selected_vvs = [6, 1, 0]

elif sector == 3: selected_vvs = [1, 2, 0]

elif sector == 4: selected_vvs = [2, 3, 7]

elif sector == 5: selected_vvs = [3, 4, 7]

else: selected_vvs = [4, 5, 0]

else: # sw_sum < 2

if thrust_error > 0:

# Based on Table 2, Column 4

if sector == 1: selected_vvs = [1, 2, 0]

elif sector == 2: selected_vvs = [2, 3, 0]

elif sector == 3: selected_vvs = [3, 4, 0]

elif sector == 4: selected_vvs = [4, 5, 0]

elif sector == 5: selected_vvs = [5, 6, 0]

else: selected_vvs = [6, 1, 0]

else:

# Based on Table 2, Column 5

if sector == 1: selected_vvs = [4, 5, 7]

elif sector == 2: selected_vvs = [5, 6, 7]

elif sector == 3: selected_vvs = [6, 1, 7]

elif sector == 4: selected_vvs = [1, 2, 7]

elif sector == 5: selected_vvs = [2, 3, 7]

else: selected_vvs = [3, 4, 7]

# Find the best voltage vector

min_cost = float('inf')

best_vv_idx = -1

for vv_idx in selected_vvs:

u_alpha, u_beta = self.VVs[vv_idx]

psi_a1_p, psi_b1_p, i_a1_p, i_b1_p, F_e_p = self.predict_states(

u_alpha, u_beta, self.lim.psi_a1, self.lim.psi_b1, i_alpha, i_beta,

self.lim.psi_a2, self.lim.psi_b2, v1

)

cost = self.cost_function(F_e_ref, psi_ref, F_e_p, (psi_a1_p, psi_b1_p))

if cost < min_cost:

min_cost = cost

best_vv_idx = vv_idx

# Update LIM state with the best voltage vector

u_alpha, u_beta = self.VVs[best_vv_idx]

_, _, self.lim.i_a1, self.lim.i_b1, self.lim.F_e = self.predict_states(

u_alpha, u_beta, self.lim.psi_a1, self.lim.psi_b1, i_alpha, i_beta,

self.lim.psi_a2, self.lim.psi_b2, v1

)

# Update mechanical model

F_load = 100 # Example load

self.lim.v1 += (self.lim.F_e - F_load - self.lim.B * self.lim.v1) / self.lim.M * self.Ts

return best_vv_idx

# --- Simulation ---

if __name__ == '__main__':

lim = LinearInductionMotor()

controller = EnhancedFCSMPDTC(lim)

# Simulation parameters

sim_time = 0.1

Ts = controller.Ts

num_steps = int(sim_time / Ts)

# References

F_e_ref = 200 # N

psi_ref = 0.8 # Wb

# Initial conditions

i_a, i_b, i_c = 0, 0, 0

v1 = 0

prev_sw_state = [0, 0, 0] # [Sa, Sb, Sc]

# Logging

time_log = []

v1_log = []

Fe_log = []

for step in range(num_steps):

best_vv_idx = controller.control(F_e_ref, psi_ref, i_a, i_b, i_c, v1, prev_sw_state)

# Update for next step

v1 = lim.v1

i_a, i_b = lim.i_a1, lim.i_b1 # In alpha-beta, for simplicity here

i_c = -i_a - i_b # Assuming balanced system

prev_sw_state = [controller.SAs[best_vv_idx], controller.SBs[best_vv_idx], controller.SCs[best_vv_idx]]

# Log data

time_log.append(step * Ts)

v1_log.append(v1)

Fe_log.append(lim.F_e)

# --- Plotting (optional, requires matplotlib) ---

try:

import matplotlib.pyplot as plt

plt.figure(figsize=(12, 8))

plt.subplot(2, 1, 1)

plt.plot(time_log, v1_log, label='Speed (v1)')

plt.title('LIM Speed')

plt.xlabel('Time (s)')

plt.ylabel('Speed (m/s)')

plt.grid(True)

plt.legend()

plt.subplot(2, 1, 2)

plt.plot(time_log, Fe_log, label='Electromagnetic Thrust (Fe)')

plt.axhline(y=F_e_ref, color='r', linestyle='--', label='Reference Thrust')

plt.title('Electromagnetic Thrust')

plt.xlabel('Time (s)')

plt.ylabel('Thrust (N)')

plt.grid(True)

plt.legend()

plt.tight_layout()

plt.show()

except ImportError:

print("Matplotlib not found. Skipping plots.")

print("Simulation finished.")