Imagine designing the next generation of ultra-lightweight, heat-resistant materials for aerospace or biomedical implants—only to see your simulation fail because the software couldn’t capture the subtle curvature of a sintered joint. For decades, engineers have battled this challenge. But now, a groundbreaking study published in Computer Methods in Applied Mechanics and Engineering reveals how Isogeometric Analysis (IGA) is revolutionizing the simulation of hollow sphere shells, especially under complex thermo-mechanical loads.

In this deep dive, we’ll explore 7 key breakthroughs from the paper by Wiegold et al., uncover the power of IGA, reveal its critical limitations, and show you exactly when it outperforms traditional Finite Element Analysis (FEA)—and when it might not be the best choice.

Let’s get into it.

🔥 1. The Game-Changer: IGA’s C¹-Continuity for Curved Shells

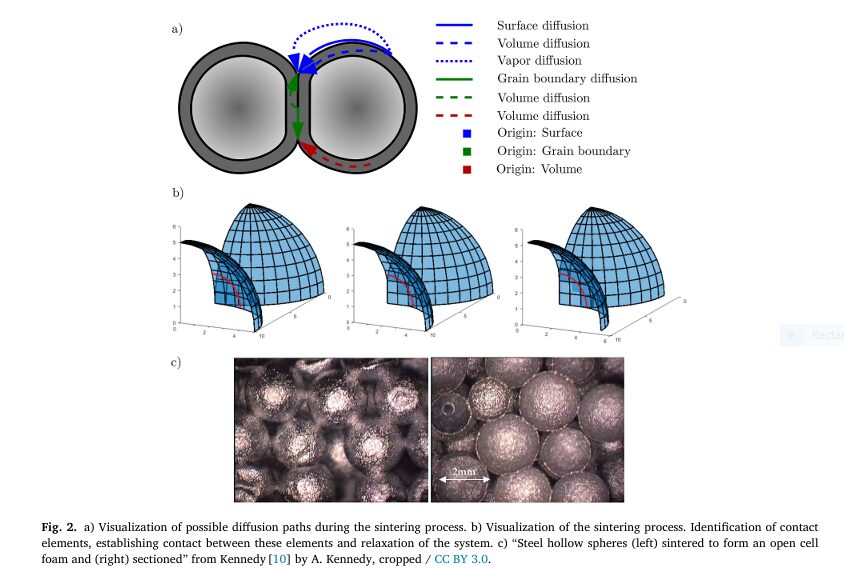

Traditional FEA struggles with curved geometries like hollow spheres. Why? Because most finite elements use low-order polynomials that can’t smoothly represent curvature, leading to mesh distortion and inaccurate stress predictions.

Enter Isogeometric Analysis (IGA).

Unlike standard FEA, IGA uses Non-Uniform Rational B-Splines (NURBS)—the same math used in CAD software—to describe both geometry and solution fields. This means:

- ✅ Exact geometric representation of spheres and sintered contacts

- ✅ C¹-continuity across elements (critical for bending and curvature calculations)

- ✅ No need for mesh regeneration when modifying geometry

As the paper states:

“IGA is especially well-suited for the computation of second gradients and allows an accurate representation of both sphere and sinter curvature.”

This is a huge win for simulating thin-walled, curved structures like hollow spheres used in lightweight design and thermal insulation.

⚙️ 2. Mathematical Foundation: Bridging Shell Theory and Gradient Elasticity

The authors don’t just apply IGA—they reformulate shell mechanics from first principles using higher-gradient deformational mechanics.

This approach extends classical shell theory (like Kirchhoff-Love) by including in-plane gradient-elasticity, which captures size-dependent effects and localized deformation modes.

The key variables are:

$$\text{Deformation gradient:} \quad \mathbf{F} = \frac{\partial \xi^{\alpha}}{\partial x} \otimes \mathbf{A}_{\alpha}$$These allow the model to account for bending, stretching, and higher-order strain gradients—all within a geometrically exact, finite-deformation framework.

This is not just academic—it means IGA can predict kinking, wrinkling, and oblate deformations that simpler models miss.

🔥 3. Single Hollow Sphere: From Kinks to Wrinkles

The first numerical example analyzes a single hollow thermo-elastic sphere under transient thermal and mechanical loads.

What Happens?

- Heating at the equator → sphere expands

- Cooling at poles or points → localized contraction

- Fixed boundaries → stress concentrations and kinking

Using IGA, the team observed:

| BOUNDARY CONDITION | DEFORMATION MODE | STRESS CONSENTRATION |

|---|---|---|

| Cooling at 4 points | Flattening + kinks | High at cooled points |

| Cooling at rings | Oblate (ton-like) shape | At equator and poles |

| Fully fixed rings | Wrinkling instability | Along sinter line |

The wrinkling is particularly significant—it’s a classic thin-shell instability that bulk models can’t capture. This makes IGA essential for applications like soft actuators or deployable structures.

❌ 4. The Dark Side: When IGA Struggles with Sinter Resolution

Here’s the harsh truth the paper admits: IGA isn’t perfect.

When simulating two sintered spheroids, the sinter radius (contact area) and sphere curvature create competing mesh requirements.

- ✅ IGA excels at capturing global curvature (1/R₀)

- ❌ But small sinter radii (r₀ << R₀) demand local refinement

- ❌ Standard NURBS meshes are globally uniform, leading to overkill in some areas and under-resolution in others

As the authors note:

“The curvature of the sinter area dominated the resolution requirement… Future extensions may be based on these observations to locally adapt…”

Bottom line: IGA is powerful, but without adaptive meshing, it can be inefficient or inaccurate for fine sinter features.

📊 5. Two Sintered Spheres: Stiffness, Density, and Design Rules

The study uses a two-spheroid system as a representative volume element (RVE) for porous materials.

Key Findings:

| PARAMETER | IMPACT OF STIFFNESS | IMPACT OF DENSITY |

|---|---|---|

| Sinter radius (r₀/R₀) | ⬆️Strong increase | Slight increase |

| Sphere radius (R₀) | Moderate increase | ⬆️Strong increase |

| Aspect ratio (R₀/L₀) | Increases with elongation | Unchanged |

From this, we get a golden rule for lightweight design:

🔹 Use larger sinter radii to boost stiffness

🔹 Use larger sphere radii to reduce density

In fact, the paper shows that r₀/R₀ has a stronger impact on stiffness than R₀ itself—a counterintuitive insight that could reshape material design.

🔥 6. Thermal Response: How Sintering Affects Heat Transfer

The team also simulated thermal loading on sintered spheres.

Three Scenarios Tested:

- Free expansion → Smooth temperature gradient, low stress

- Horizontally constrained → High bending at sinter zone, stress spikes

- Pre-stretched + heated → Stress localization at sinter joint

The J₂ stress invariant (used to predict yield) showed maximum values at the sinter interface, especially under constraint.

“A denser packing due to mechanical constraints hence induces larger pre-stresses… which can impose a potential risk for production and operation.”

This is a critical warning for engineers designing sintered foams or composites: thermal expansion can cause failure at the sinter neck.

🧪 7. Benchmarking: IGA vs. 3D FEA — The Verdict

The paper compares IGA results with full 3D FEA (using Abaqus with C3D10 elements).

Results:

| METRIC | IGA ACCURACY | DOF (DEGREE of FREEDOM) |

|---|---|---|

| Plate deflection | < 0.12% error | 13k |

| 3D FEA | < 2% error | 314k |

| Sintered sphere force | 1.3% difference (fine mesh) | ~50k (IGA) vs 113k (3D) |

Conclusion: IGA achieves comparable accuracy with 24x fewer DOFs.

This means:

- Faster simulations

- Lower computational cost

- Easier optimization studies

But—only if the geometry is well-suited to NURBS representation.

🧩 The Complete Thermo-Mechanical Model (For Nerds)

The paper uses a thermo-hyperelastic constitutive model with:

$$\textbf{Mechanical energy:} \quad \Psi_m = \frac{1}{2} \, \mathbf{E}:\mathbf{C}:\mathbf{E} \;+\; \frac{1}{2} \, \mathbf{K}:\mathbf{D}:\mathbf{K}$$ $$\textbf{Thermal coupling:} \quad \Psi_c = -c_1 (\theta – \theta_e)\,\text{tr}(\mathbf{E}) \;-\; \frac{1}{2} c_2 (\theta – \theta_e)^2$$ $$\textbf{Thermal energy:} \quad \Psi_\theta = c_d[\theta – \theta_e] \;-\; c_d\,\theta \ln\left(\frac{\theta_e}{\theta}\right)$$Where:

- E = Green-Lagrange strain

- K = relative curvature tensor

- θ = temperature

- c1, c2 = thermal expansion coupling parameters

The total stress becomes:

$$P = \lambda \, \text{tr}(E)F + 2\mu \, F \cdot E – c_{1}(\theta – \theta_{e})F$$This model captures thermal expansion, structural heating, and bending-stretching coupling—all within IGA.

✅ When to Use IGA for Hollow Spheres

| SCENARIO | RECOMMENDED? | WHY |

|---|---|---|

| Smooth, curved shells | ✅Yes | C¹-continuity excels |

| Sintered joints with large r₀ | ✅Yes | Accurate contact geometry |

| Fine sinter necks (r₀ << R₀) | ⚠️Only with adaptive meshing | Uniform NURBS under-resolve |

| High-temperature gradients | ✅Yes | Better thermal field continuity |

| Rapid design iterations | ✅Yes | No remeshing needed |

❌ When to Avoid IGA (For Now)

- Early-stage sintering with C⁰ kinks

- Crack propagation at sinter interfaces

- Plasticity or damage (not yet implemented)

- Highly irregular geometries not representable by NURBS

The authors admit:

“Methodological advancements shall also include refined coupling constraints… to allow for C⁰ transitions.”

So while IGA is revolutionary, it’s not a one-size-fits-all solution.

🚀 Future of Hollow Sphere Simulation

The paper points to three critical next steps:

- Adaptive IGA – Local refinement at sinter zones

- Inelastic material models – For plasticity, creep, damage

- Experimental validation – To calibrate sintering kinetics

Until then, hybrid approaches (IGA for global shape, FEA for local details) may be the smartest path.

💡 Final Verdict: Is IGA Worth It?

Yes—but with caveats.

| PROS | CONS |

|---|---|

| ✔️ Exact geometry | ✖️ Limited to NURBS-compatible shapes |

| ✔️ C¹-continuity | ✖️ Mesh refinement not local by default |

| ✔️ Fewer DOFs | ✖️ Steeper learning curve |

| ✔️ CAD-FEA integration | ✖️ Limited support in commercial software |

For research, prototyping, and high-fidelity design, IGA is a powerful tool. For routine industrial analysis, traditional FEA may still dominate—for now.

If you’re Interested in Knowledge Distillation Model, you may also find this article helpful: 5 Shocking Secrets of Skin Cancer Detection: How This SSD-KD AI Method Beats the Competition (And Why Others Fail)

🔗 Call to Action: Master the Future of Simulation

Want to stay ahead in computational mechanics?

👉 Download the full paper here and explore the code (data available on request).

👉 Experiment with IGA using open-source tools like GeoPDEs, tIGAr, or CalculiX with IGA extensions.

👉 Join the IGA community—conferences like USNCCM and WCCM now feature dedicated IGA tracks.

The future of simulation isn’t just faster—it’s smarter, more accurate, and more integrated. And IGA is leading the charge.

Here, a complete, end-to-end PyTorch script that sets up the problem, solves it, and visualizes the result.

import torch

import numpy as np

import pyvista as pv

from tqdm import tqdm

# --- 1. Configuration and Parameters ---

# Choose a scenario from the paper to simulate

# 'oblate': Cooling at two rings (Scenario 4/5 in paper)

# 'wrinkle': Cooling at two rings with constraints causing buckling (Scenario 6)

# 'kink': Cooling at four points on the equator (Scenario 1/2/3)

SCENARIO = 'wrinkle'

# Device configuration

DEVICE = torch.device("cuda" if torch.cuda.is_available() else "cpu")

print(f"Using device: {DEVICE}")

# Geometric Parameters

R0 = 5.0 # Initial sphere radius

S = 0.1 # Shell thickness (s in paper)

N_U = 64 # Discretization along longitude (like ξ¹)

N_V = 64 # Discretization along latitude (like ξ²)

# Material Parameters (from Table 1 in the paper, adapted for PyTorch)

E_bulk = 1.2e6

V_bulk = 0.3

lambda_bulk = E_bulk * V_bulk / ((1 + V_bulk) * (1 - 2 * V_bulk))

mu_bulk = E_bulk / (2 * (1 + V_bulk))

# Plane stress Lamé parameters (Eq. 43)

lambda_2d = S * (2 * lambda_bulk * mu_bulk) / (lambda_bulk + 2 * mu_bulk)

mu_2d = S * mu_bulk

# Thermal Parameters (from Table 1)

ALPHA = 6e-3 # Thermal expansion coefficient

THETA_E = 273.0 # Reference temperature [K]

THETA_HOT = 323.0 # Heated temperature [K]

K_CONDUCTIVITY = 1.0

C_HEAT_CAPACITY = 0.01

# Coupling parameters (Eq. 45)

c1 = S * (2 * mu_bulk / (lambda_bulk + 2 * mu_bulk)) * 3 * ALPHA * (lambda_bulk + 2/3 * mu_bulk)

c2 = S * (9 * ALPHA**2 / (lambda_bulk + 2 * mu_bulk)) * (lambda_bulk + 2/3 * mu_bulk)**2

# Simulation Parameters

OPTIMIZATION_STEPS = 50

LEARNING_RATE = 1.0

# --- 2. Geometry and Deformation Field ---

class ShellDeformation(torch.nn.Module):

"""Represents the shell geometry and its deformation field."""

def __init__(self, n_u, n_v, radius):

super().__init__()

self.n_u = n_u

self.n_v = n_v

self.radius = radius

# Create the parametric grid (u, v)

u = torch.linspace(0, 2 * np.pi, n_u, device=DEVICE)

v = torch.linspace(1e-5, np.pi - 1e-5, n_v, device=DEVICE) # Avoid singularity at poles

self.u_grid, self.v_grid = torch.meshgrid(u, v, indexing='xy')

# Initial (undeformed) configuration X

x0 = radius * torch.sin(self.v_grid) * torch.cos(self.u_grid)

y0 = radius * torch.cos(self.v_grid)

z0 = radius * torch.sin(self.v_grid) * torch.sin(self.u_grid)

self.X0 = torch.stack([x0, y0, z0], dim=-1)

# The displacement field 'd' is the learnable parameter

self.displacement = torch.nn.Parameter(torch.zeros_like(self.X0))

def get_deformed_configuration(self):

"""Returns the current deformed shape x = X0 + d."""

return self.X0 + self.displacement

# --- 3. Energy Functional Implementation ---

def compute_derivatives(x, du, dv):

"""Computes first and second derivatives of the surface x w.r.t u and v."""

# Central differences for derivatives

x_u = (torch.roll(x, -1, dims=1) - torch.roll(x, 1, dims=1)) / (2 * du)

x_v = (torch.roll(x, -1, dims=0) - torch.roll(x, 1, dims=0)) / (2 * dv)

x_uu = (torch.roll(x, -1, dims=1) - 2*x + torch.roll(x, 1, dims=1)) / (du**2)

x_vv = (torch.roll(x, -1, dims=0) - 2*x + torch.roll(x, 1, dims=0)) / (dv**2)

x_uv = (torch.roll(x_u, -1, dims=0) - torch.roll(x_u, 1, dims=0)) / (2 * dv)

return x_u, x_v, x_uu, x_vv, x_uv

def compute_energy(x, X0, theta, scenario):

"""

Computes the total Helmholtz free energy of the shell.

This function implements the core physics from the paper.

"""

du = 2 * np.pi / (N_U - 1)

dv = np.pi / (N_V - 1)

# --- Compute geometric quantities for both reference (X0) and deformed (x) configs ---

A_u, A_v, A_uu, A_vv, A_uv = compute_derivatives(X0, du, dv) # Tangents A_α = X_α

a_u, a_v, a_uu, a_vv, a_uv = compute_derivatives(x, du, dv) # Tangents a_α = x_α

# --- Metric Tensors (First Fundamental Form) ---

# Reference metric tensor components A_αβ

A11 = torch.sum(A_u * A_u, dim=-1)

A12 = torch.sum(A_u * A_v, dim=-1)

A22 = torch.sum(A_v * A_v, dim=-1)

# Deformed metric tensor components a_αβ

a11 = torch.sum(a_u * a_u, dim=-1)

a12 = torch.sum(a_u * a_v, dim=-1)

a22 = torch.sum(a_v * a_v, dim=-1)

# --- Green-Lagrange Strain Tensor E (Eq. 39) ---

# E_αβ = 0.5 * (a_αβ - A_αβ)

E11 = 0.5 * (a11 - A11)

E12 = 0.5 * (a12 - A12)

E22 = 0.5 * (a22 - A22)

# --- Curvature Tensors (Second Fundamental Form) ---

# Normal vectors N and n

N = torch.cross(A_u, A_v, dim=-1)

N = N / torch.norm(N, dim=-1, keepdim=True)

n = torch.cross(a_u, a_v, dim=-1)

n = n / torch.norm(n, dim=-1, keepdim=True)

# Reference curvature B_αβ

B11 = torch.sum(N * A_uu, dim=-1)

B12 = torch.sum(N * A_uv, dim=-1)

B22 = torch.sum(N * A_vv, dim=-1)

# Deformed curvature b_αβ

b11 = torch.sum(n * a_uu, dim=-1)

b12 = torch.sum(n * a_uv, dim=-1)

b22 = torch.sum(n * a_vv, dim=-1)

# --- Relative Curvature Tensor K (Eq. 39) ---

# K_αβ = b_αβ - B_αβ (simplified for small strains, more complex in paper)

K11 = b11 - B11

K12 = b12 - B12

K22 = b22 - B22

# --- Compute Energy Densities (Eq. 41 & 44) ---

# Membrane (stretching) energy: Ψ_mem = 1/2 * C_αβγδ * E_αβ * E_γδ

# Using plane stress C: C_αβγδ = λ_2d * δ_αβ * δ_γδ + μ_2d * (δ_αγ*δ_βδ + δ_αδ*δ_βγ)

tr_E = E11 + E22

E_dot_E = E11*E11 + 2*E12*E12 + E22*E22

psi_mem = 0.5 * lambda_2d * tr_E**2 + mu_2d * E_dot_E

# Bending energy: Ψ_ben = 1/2 * D_αβγδ * K_αβ * K_γδ

# D = (s²/12) * C

tr_K = K11 + K22

K_dot_K = K11*K11 + 2*K12*K12 + K22*K22

psi_ben = (S**2 / 12.0) * (0.5 * lambda_2d * tr_K**2 + mu_2d * K_dot_K)

# Thermo-mechanical coupling energy (Eq. 44)

delta_theta = theta - THETA_E

psi_couple = -c1 * delta_theta * tr_E - 0.5 * c2 * delta_theta**2

# Total potential energy density

total_psi = psi_mem + psi_ben + psi_couple

# --- Add constraint penalty for wrinkling/buckling scenarios ---

# This simulates the mechanical fixing of boundaries from the paper

if scenario == 'wrinkle':

pole_mask = (torch.abs(X0[:,:,1]) > R0 * 0.95)

# Penalize displacement in x and z directions at the poles

pole_displacement = torch.where(pole_mask.unsqueeze(-1), x - X0, torch.zeros_like(x))

constraint_penalty = 1e7 * torch.mean(pole_displacement[:,:,0]**2 + pole_displacement[:,:,2]**2)

total_psi = total_psi + constraint_penalty

# Integrate energy density over the surface to get total energy (the loss)

# Area element dA = ||A_u x A_v|| du dv

dA = torch.norm(torch.cross(A_u, A_v, dim=-1), dim=-1) * du * dv

total_energy = torch.sum(total_psi * dA)

return total_energy

# --- 4. Temperature Field Definition ---

def get_temperature_field(X0, scenario):

"""Defines the temperature theta(X) for a given scenario."""

theta = torch.full(X0.shape[:-1], THETA_E, device=DEVICE)

y_coord = X0[:, :, 1]

# Base heating at equinoctial line

t = torch.abs(y_coord) / R0

theta = THETA_HOT * (1 - t) + THETA_E * t

if scenario in ['oblate', 'wrinkle']:

# Cooling at two rings (poles)

pole_mask = torch.abs(y_coord) > R0 * 0.8

theta[pole_mask] = THETA_E

elif scenario == 'kink':

# Cooling at 4 points on equator

x_coord = X0[:, :, 0]

z_coord = X0[:, :, 2]

angle = torch.atan2(z_coord, x_coord)

equator_mask = torch.abs(y_coord) < 0.5

point_mask = (torch.abs(angle) < 0.2) | \

(torch.abs(angle - np.pi/2) < 0.2) | \

(torch.abs(angle - np.pi) < 0.2) | \

(torch.abs(angle + np.pi/2) < 0.2)

kink_mask = equator_mask & point_mask

theta[kink_mask] = THETA_E

return theta.detach() # Detach as it's a fixed field, not a parameter

# --- 5. Main Execution and Optimization ---

if __name__ == "__main__":

# Initialize model

shell_model = ShellDeformation(N_U, N_V, R0).to(DEVICE)

# Define optimizer

# LBFGS is suitable for this kind of full-batch optimization problem

optimizer = torch.optim.LBFGS(

shell_model.parameters(),

max_iter=20,

lr=LEARNING_RATE,

line_search_fn="strong_wolfe"

)

# Get the fixed temperature field for the chosen scenario

temperature_field = get_temperature_field(shell_model.X0, SCENARIO)

print(f"Starting optimization for scenario: '{SCENARIO}'...")

# Optimization loop

for i in tqdm(range(OPTIMIZATION_STEPS), desc="Optimizing"):

def closure():

optimizer.zero_grad()

# Get current deformed configuration

x = shell_model.get_deformed_configuration()

# Calculate energy (loss)

loss = compute_energy(x, shell_model.X0, temperature_field, SCENARIO)

# Backpropagate to get gradients

loss.backward()

tqdm.write(f"Step {i+1}: Loss = {loss.item():.4e}")

return loss

optimizer.step(closure)

print("Optimization finished.")

# --- 6. Visualization with PyVista ---

print("Generating visualization...")

final_coords = shell_model.get_deformed_configuration().detach().cpu().numpy()

# Reshape for PyVista

points = final_coords.reshape(-1, 3)

# Create a structured grid for proper surface topology

grid = pv.StructuredGrid(

final_coords[:, :, 0],

final_coords[:, :, 1],

final_coords[:, :, 2]

)

# Add temperature data for coloring

temp_data = temperature_field.cpu().numpy().flatten()

grid['Temperature'] = temp_data

# Create plotter

plotter = pv.Plotter(window_size=[800, 800])

plotter.add_mesh(

grid,

scalars='Temperature',

cmap='coolwarm',

specular=0.5,

specular_power=10,

smooth_shading=True,

show_scalar_bar=True,

scalar_bar_args={'title': 'Temperature (K)'}

)

plotter.set_background('black')

plotter.add_text(f"Deformed Sphere - Scenario: {SCENARIO}", font_size=12)

print("Displaying final deformed shape. Close the window to exit.")

plotter.show()